High-quality air samples for detecting smoke in ventilation

2022-09-22

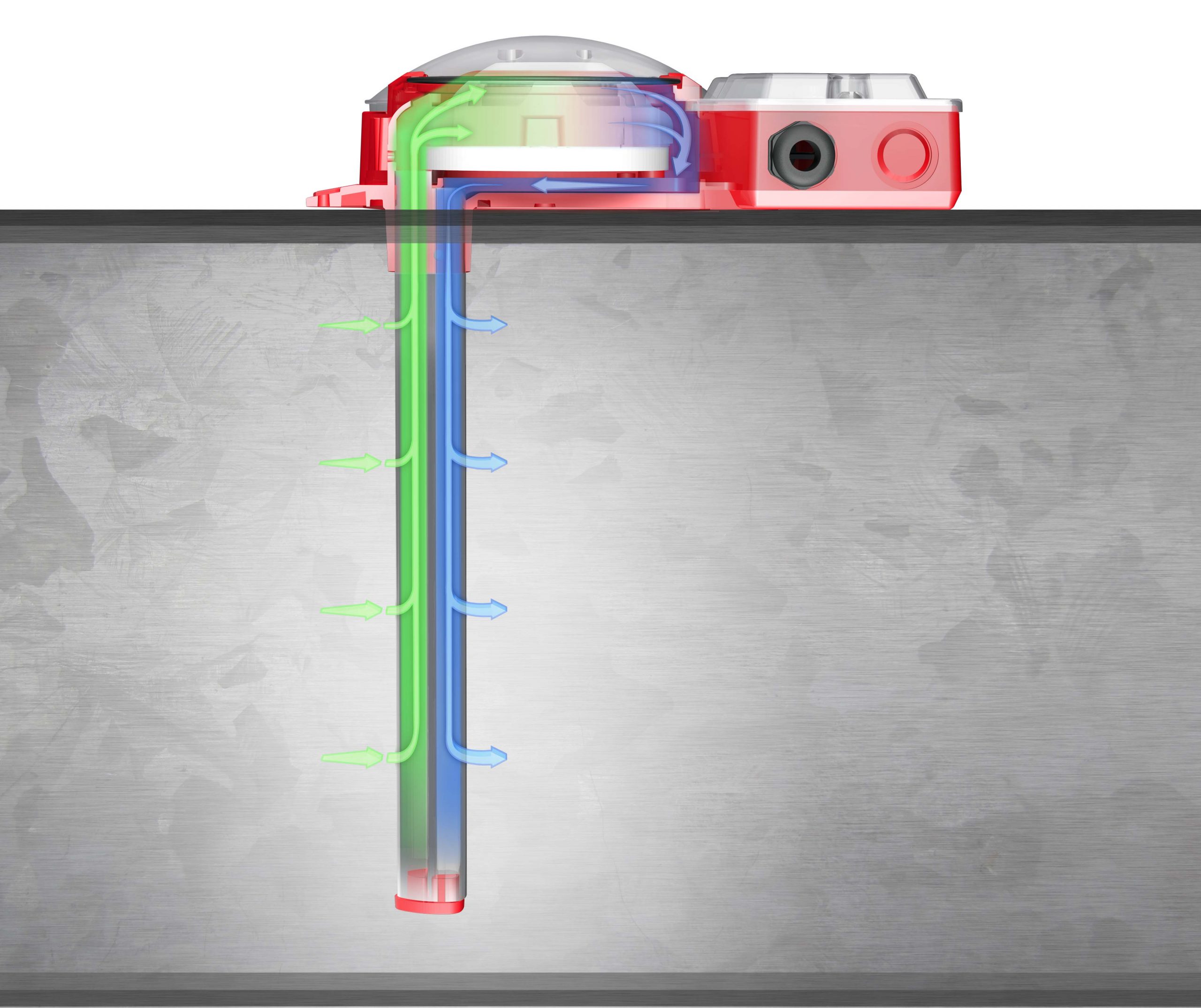

To detect, and also prevent, smoke from spreading in ventilation ducts it is crucial that the smoke detection system has access to high-quality air samples. An air probe in the form of a tube, also called a venturi tube, is an effective way of continuously collecting samples of air. By using the air flow in the ventilation duct, high and low air pressure is created in the venturi tube. That allows the venturi tube to provide air samples perfect for analyzing potential hazardous particles.

An air probe in the form of a tube collects air samples in ventilation ducts

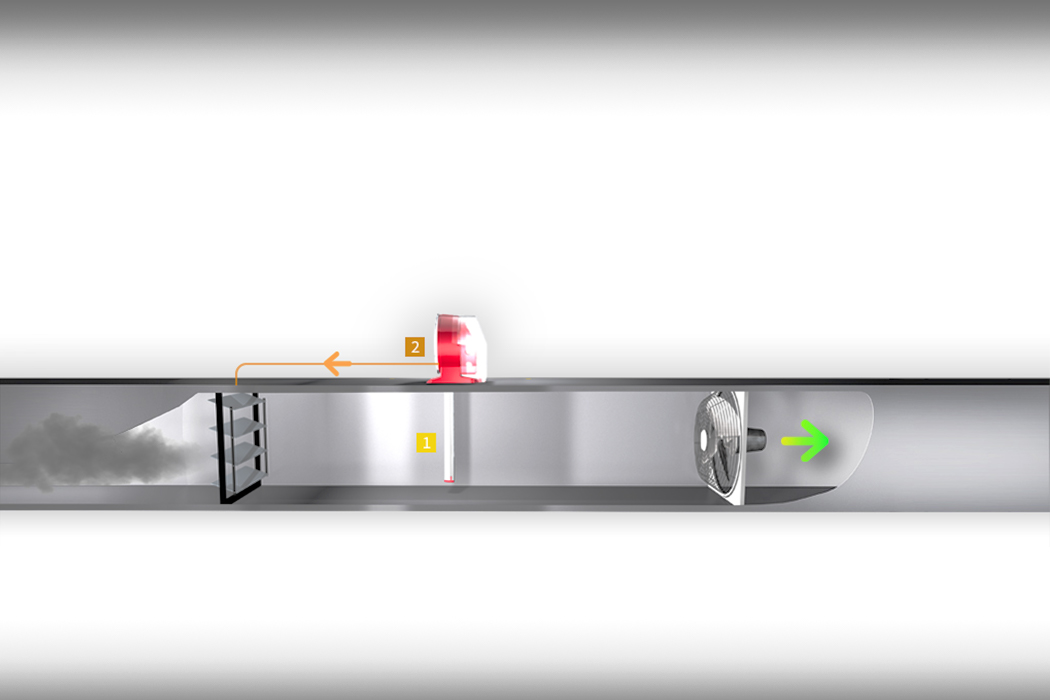

Generally, a smoke detection system consists of an air probe 1 and a smoke detector housing 2 with an integrated or external control unit. The smoke detector itself cannot be placed inside the ventilation duct due to a large amount of dust and particles in the air that would get stuck in the detector, preventing it from analyzing the air. Instead, an air probe in the form of a tube is placed inside the ventilation duct. The tube collects air samples from the duct that are sent to the smoke detector which is placed on the outside of the ventilation duct.

The smoke detector searches for potential hazardous particles in the air. If smoke is detected, the smoke detector sends a signal to the control unit, which by means of relays can close dampers, stop/start fans and forward the alarm to, for example, a DDC (Direct Digital Controller).

The Venturi effect - airflow created by combining high and low pressure

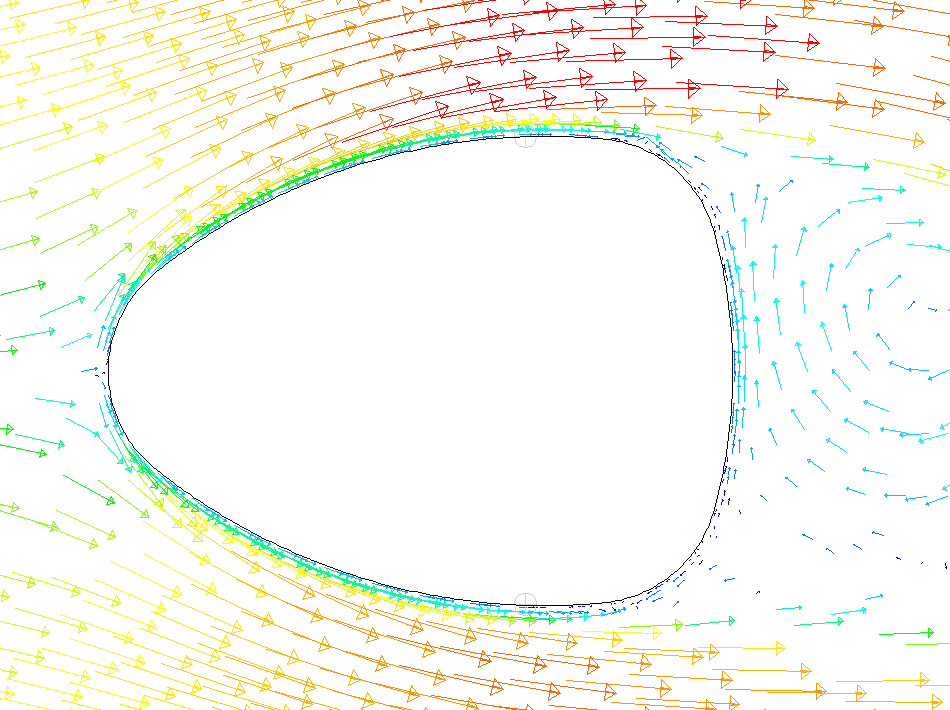

The aerodynamic design of the housing and the tube are crucial in order to detect small levels of smoke particles in the air at an early stage. The tube collecting air samples from the duct, also known as a venturi tube, is based on the Venturi effect. The Venturi effect is named after the Italian physicist Giovanni Battista Venturi (1746–1822). The Venturi effect is a reduction of air pressure as a result of air flowing at an increased velocity through a constricted section of a tube. Thus, the only thing a venturi tube needs to function is air flow in the ventilation duct of at least 0,2 meters per second. There are no pumps or mechanics attached to the tube that require energy. It does not generate any noise and there is no wear on the tube that might require service.

Three aerodynamic slits collect air in an effective way

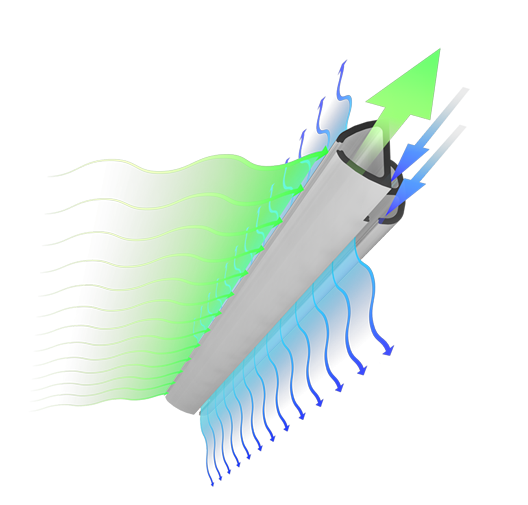

Calectro’s smoke detection system called Uniguard has a patented venturi tube which consists of three separated channels combined into one larger tube, formed as a triangle. Each channel is fitted with an aerodynamic slit. When the airflow hits the front channel, it creates a high air pressure, which pushes the air to the smoke detector. When the air in the ventilation duct passes on each side of the tube, where the other two channels are located, the speed of the air increases which leads to low air pressure (the venturi effect), helping to draw the air back from the smoke detector to the ventilation duct.

The design of Calectro’s venturi tube, with two channels creating low pressure instead of one, has been engineered in detail and gone through multiple tests to deliver the best possible result. We found that this is the most effective way of drawing air from the depths of the entire ventilation duct and delivering it to the smoke detector. Our design facilitates the discovery of hazardous particles even in small doses and at very low airflows.

Products for creating a safe, healthy and comfortable indoor climate

Calectro AB was founded in 1969 and has been an expert in duct smoke detection and HVAC components ever since. We design and manufacture our products based on our customers’ needs and offer them to actors within the automation and control industry all over the world. Calectro’s products exist everywhere in your day-to-day life, helping to create a safe, healthy and comfortable indoor climate.

Would you like to know more about Calectro and our smoke detection systems for ventilation? Please continue to browse our website for more information and ways to contact us. Also, keep an eye out for the follow-up article where I describe the differences between having a venturi tube that consists of 1 and 2 tubes.

Related articles

-

Technology & products

2021-09-22

Four common questions about duct smoke detector sensitivity

Read more -

Technology & products

2021-01-13

Leading the way in fire safety and building automation (Part 1)

Read more